Reliable Welding Inspection Service for Quality Assurance

Discover the Advantages of Different Sorts Of Welding Providers for Your Organization

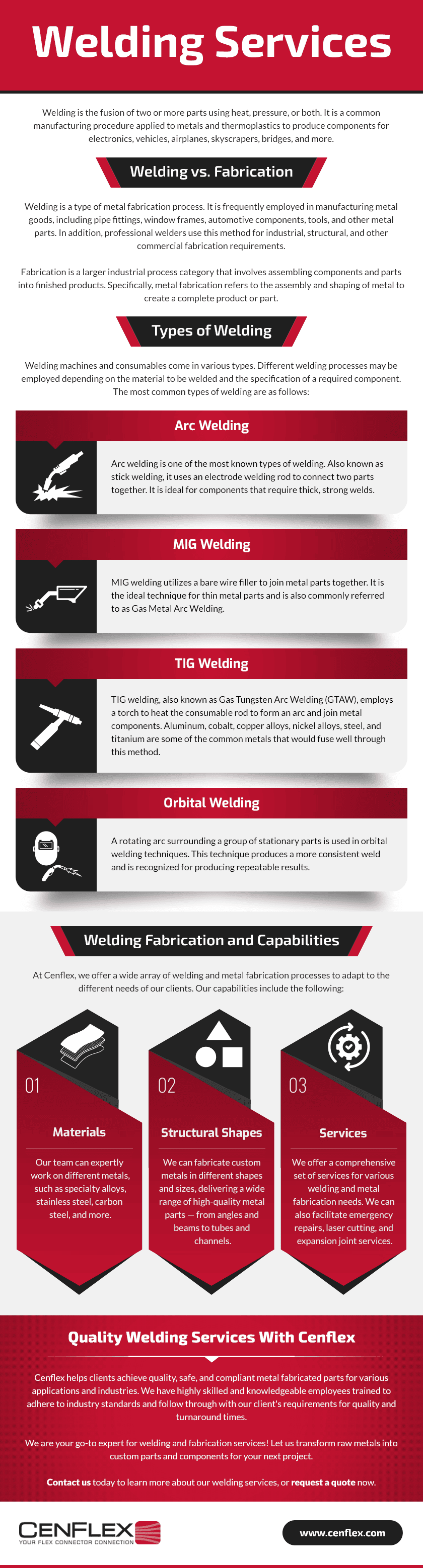

In the realm of commercial operations, the choice of welding solutions plays a pivotal function in figuring out the quality and effectiveness of your business processes. Each welding method, from MIG to TIG, Arc, and Spot welding, supplies unique benefits that provide to specific requirements and demands.

MIG Welding Benefits

MIG welding, likewise referred to as Gas Metal Arc Welding (GMAW), uses numerous benefits to organizations seeking effective and top quality welding services. One main benefit of MIG welding is its flexibility in taking care of various sorts of steels, consisting of stainless steel, light weight aluminum, and mild steel. This versatility makes MIG welding a preferred choice for markets with varied welding needs.

In addition, MIG welding is an affordable choice as a result of its reliable use of consumables such as filler product and protecting gas. This effectiveness converts to cost savings for businesses in the lengthy run. Overall, MIG welding's mix of versatility, speed, convenience of use, and cost-effectiveness makes it a recommended option for many welding applications.

TIG Welding Benefits

Tungsten Inert Gas (TIG) welding offers specific control and outstanding quality in welding services for organizations requiring careful and high-standard welds - Welding Inspection Service. TIG welding stands apart for its ability to produce clean and specific welds without spatter or stimulates, making it ideal for applications where aesthetic appeals and precision are vital. Among the vital advantages of TIG welding is its flexibility in welding different kinds of steels, including stainless-steel, aluminum, copper, and exotic steels, offering services with an adaptable welding solution for various projects

In addition, TIG welding makes it possible for welders to function with thinner materials effectively, as the procedure allows for reduced warmth input and much better control over the welding arc. In general, the precise control, high-quality welds, and convenience make TIG welding a favored selection for organizations looking to attain excellent welding outcomes.

Arc Welding Pros

Place Welding Advantages

Place welding offers many advantages for services looking for accurate and reliable joining of metal parts in their manufacturing procedures. This welding approach is highly economical due to its fast execution, marginal need for substantial prep work, and lower energy usage contrasted to various other welding techniques (Welding Inspection Service). Area welding additionally supplies a clean and neat surface, making it optimal for applications where aesthetics are vital

Among the key benefits of area welding is its capacity to develop strong and resilient bonds in between steel surfaces. The process straight from the source generates a concentrated warm resource, causing a local weld that decreases damage to the surrounding areas. This focused heat application also decreases the danger of bending or distortion in the bonded products, making certain the honesty of the last item.

Moreover, spot welding is highly versatile and can be used on a vast array of alloys and metals, including light weight aluminum, copper, and steel. Its adaptability makes it a popular selection for sectors such as auto, electronic devices, and aerospace, look at more info where accuracy and performance are paramount. Overall, the advantages of place welding make it a useful possession for companies looking to enhance their production abilities.

Welding Service Selection Variables

One more element to think about is the dimension and intricacy of the elements being welded. Some welding methods are much better matched for complex and small-scale tasks, while others are a lot more effective for larger and more uncomplicated frameworks. Consider the rate and effectiveness of the welding process. Relying on your production requirements, picking a welding service that can fulfill your timeline and result demands is critical for preserving productivity. Assess the cost-effectiveness of various welding services to make sure that you are getting the ideal value for your financial investment. By very carefully considering these variables, you can select one of the most appropriate welding solution for your company demands.

Final Thought

To conclude, recognizing the advantages of various kinds of welding services can substantially profit businesses in their decision-making process. MIG welding provides effectiveness and speed, TIG welding supplies high precision and tidy welds, arc welding is functional and cost-efficient, and area welding is excellent for signing up with slim products. By taking into consideration these variables, organizations can pick one of the most ideal welding solution to satisfy their certain requirements and demands.

MIG welding, likewise known as Gas Metal Arc Welding (GMAW), offers numerous advantages to organizations looking for effective and top notch welding services. One of the essential advantages of TIG welding is its adaptability in welding different types of steels, consisting of stainless steel, aluminum, copper, and exotic steels, supplying services with a versatile welding option for different tasks.

Arc welding is recognized for its high welding rate, enabling reliable conclusion of welding tasks (Welding Inspection Service). On the whole, the pros of arc content welding make it a useful welding service for businesses looking for a functional, economical, and efficient welding remedy

MIG welding offers efficiency and speed, TIG welding gives high precision and tidy welds, arc welding is flexible and affordable, and spot welding is suitable for joining slim products.